operations and maintenance

be on the front lines of tackling today’s energy challenges

use your knowledge and skills to help create energy solutions that forge new paths

Rotating Equipment Reliability Analyst

Richmond, California

R000056663

At Chevron, we put our people first. At the core of our success lies a commitment to delivering impeccable operations and maintenance. From upholding the physical well-being of our community to constantly innovating for enhancements, we are dedicated to supporting a sustainable energy future with the right team members.

success profile

At Chevron, we are dedicated to the success of our teams – we believe these attributes enhance the team to thrive in a competitive, safety-focused environment while collaborating for individual growth and advancement.

- Team player

- Communicator

- Problem-Solver

- Detail-oriented

- Self-starter

- Adaptable

Culture

-

Step into Chevron each day for a hands-on opportunity to collectively grow, collaborate with enthusiasm, and enhance your skills.

Join the journey to elevate our energy company's global reputation, where our outstanding people, strong partnerships, and top-tier performance take center stage.

Built on empowering values, Chevron encourages connections not only within your team but also within the communities and environments we proudly serve.

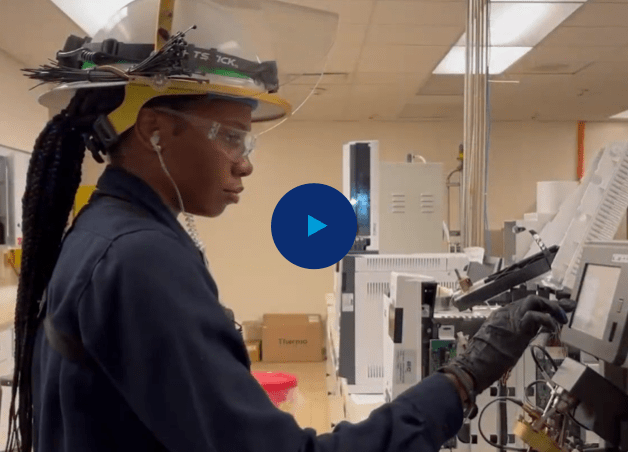

hear from our people

At Chevron, our greatest resource is our diverse people community. Our network of professionals execute highly skilled tasks to guarantee the safety and seamless continuity of our operations while working together to ensure excellence.

benefits

Yep, we’ve got the same benefits all those fancy office jobs have. And more. When you have everything you need, you can go a lot further than you’d ever expect.

-

medical and financial

- Medical, Dental, and Vision care coverage

- Retirement and Savings Plans

- Domestic Partner Benefits

- Annual Incentive Awards

- Disability, Life, and Accident Insurance

- Education Assistance and Support

-

learning and development

- Advanced hands-on training and Career Development

- Internal Promotion Opportunities

-

work-life balance success

- Paid vacations and holiday

- Access to counseling services and treatment facilities

- Programs to help you balance your work and personal life

- Health and wellness resources and programs, including fitness centers at many major locations

Rotating Equipment Reliability Analyst

Richmond, California

R000056663

Supports larger customers/clients and may lead functional projects under infrequent supervision. Developing a detailed knowledge of the work function.

Chevron is accepting online applications for the position Rotating Equipment Reliability Analyst through 05/10/2024 at 11:59 p.m. (PST).

Rotating Equipment Reliability (RER) Analysts are responsible for coordinating and leading the machinery reliability program for their assigned process unit(s). These responsibilities include providing technical support/coverage of unplanned/emergency machinery situations, developing and implementing machinery solutions to machinery worst actors, developing long-term machinery reliability recommendations, conducting machinery diagnostic analysis and troubleshooting, and contributing to the implementation of system-wide reliability programs and strategies. The RER Analyst guides preventive and predictive machinery maintenance determines root causes of machinery failures and develops solutions to prevent a recurrence.

Responsibilities for this position may include but are not limited to:

Critical Machinery Troubleshooting – Support maintenance and operations teams during troubleshooting efforts for high criticality equipment outages focusing on restoring the equipment and plants to service while finding long-term fixes to best prevent reoccurrences.

Record-Keeping – Document machinery history accurately and completely with an emphasis on root cause identification and scope of repairs. Maintains machinery files, prioritized worst actor lists, and surveillance information in an up-to-date fashion. Completes all associated paperwork (ACD, MOC, etc.) with design changes and upgrades.

Design Review – Analyzes machinery history for assigned areas and develops prioritized reliability improvement opportunities. Reviews new machinery installations to optimize machinery reliability through adherence to Refinery and

Corporate specifications/standards. Provide support for HAZOPS, PHA, HSE, and Incident Investigations as required.

Root Cause Failure Analysis – Support formal loss investigations for equipment difficult issues including seal failures of pumps, maintenance rework, and repeat failures.

Quality Assurance – Provides support to Construction Service Group and Zone Maintenance departments through the development and review of machinery repair checklists, preventive maintenance checklists, and maintenance procedures as necessary. Provides support to the Operations department through the development and review of operating procedures and checklists as necessary. Supports the safe commissioning of systems by ensuring that new or repaired equipment installations meet safety standards by participating in PSSRs.

Machinery Protection – Provides technical support to ensure that key mechanical equipment is adequately protected by reliable protection systems. Assists the Operations department in determining appropriate alarm and control limits for machinery.

Machinery Condition Monitoring and Surveillance – Performs routine condition monitoring and diagnostics of both “garden-variety” and major machinery in addition to enhanced monitoring as dictated by machine condition. Performs visual surveillance of operating equipment and breakdown inspection of failed equipment. Evaluates machinery performance.

Tracks and ensures quality offsite shop repairs.

Respond to off-shift callouts for RER assistance regarding rotating equipment issues.

Provides turnaround and capital project support.

Creates or revises PMs, job guidelines, or procedures for equipment.

Preferred Qualifications/Experience:

Vibration analyst certification (Level 1 or higher) from an approved external body.

Working knowledge of machinery analysis software and tools, and Maintenance work planning tools such as:

BN ADRE Sxp, BN System 1, Windrock MD, Prognost (major machinery surveillance)

AMS Machinery Health Manager (garden variety equipment surveillance)

Smart GEP/Maximo/SAP/ Meridium, RIMS, IMPACT

Demonstrated strong interest in machinery analysis – focus on identification of potential reliability threats, ownership and focusing on making improvements.

Experience with formal Root Cause Failure Analysis techniques (5-Why, Why Trees, TapRoot, etc.)

Excellent Planning and Organizational Skills.

Required Qualifications/Experience:

High School Diploma or Equivalent

Valid Driver's license

Strong knowledge of rotating equipment, including turbines, centrifugal compressors, reciprocating compressors, pumps, motors and other auxiliary equipment.

Experience with machinery condition monitoring and protection, including vibration analysis, oil condition monitoring and machinery performance analysis,

Capable of using databases and storing electronic data as well understanding of Excel and Word computer programs.

Relocation Options:

Relocation may be considered.

Special Considerations:

This role is located at the Richmond Refinery and follows a 4-10 work schedule.

This position is eligible to earn "compensatory time" in accordance with Refinery policy during exceptional work periods such as turnaround support and significant unplanned events.

Regulatory Disclosure for US Positions

The compensation and reference to benefits for this role is listed on this posting in compliance with applicable law. The selected candidate’s compensation will be determined based on his or her skills, experience, and qualifications. Please note that the compensation and benefits listed below are only applicable to successful candidates who are hired onto local United States payroll.

The anticipated salary range for this position is $114,500 – $196,400.

Chevron offers competitive compensation and benefits programs which includes, but is not limited to, variable pay, health care coverage, retirement plan, protection coverage, time off and leave programs, training and development opportunities and a range of allowances connected to specific work situations. Details are available at http://hr2.chevron.com/.

Regulatory Disclosure for US Positions:

Chevron is an Equal Opportunity / Affirmative Action employer. All qualified applicants will receive consideration for employment without regard to race, color, religious creed, sex (including pregnancy), sexual orientation, gender identity, gender expression, national origin or ancestry, age, mental or physical disability, medical condition, reproductive health decision-making, military or veteran status, political preference, marital status, citizenship, genetic information or other characteristics protected by applicable law.

We are committed to providing reasonable accommodations for qualified individuals with disabilities. If you need assistance or an accommodation, please email us at emplymnt@chevron.com.

Chevron participates in E-Verify in certain locations as required by law.

Default Terms and Conditions

We respect the privacy of candidates for employment. This Privacy Notice sets forth how we will use the information we obtain when you apply for a position through this career site. If you do not consent to the terms of this Privacy Notice, please do not submit information to us.

Please access the Global Application Statements, select the country where you are applying for employment, then acknowledge that you have read and agree to the country specific statement by checking the box below.

jobs for you

Do you have any jobs saved yet? Start looking now! Once you've found one you're interested in, click the save this job button or icon. You can find them on the search results or job description pages.

Recently viewed jobs will appear here once you have visited a job description page.

No jobs nearby.

view all available opportunities

that’s not all there’s more to our story

-

life at chevron

Our strategies guide our actions to deliver industry leading results.

life at chevron

-

resources

We invest in, develop and empower our highly competent workforce.

resources

-

career development

Tackle global, real world problems facing humanity as we know it.

career development

-

diversity and inclusion

We learn from and respect the cultures in which we operate. We have an inclusive work experience that values uniqueness and diversity.

diversity and inclusion